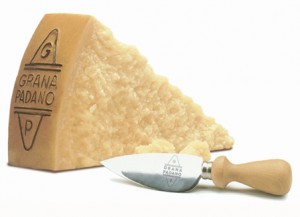

Grana Padano

The origin of Grana Padano is a fascinating tale, dating back to around 1100 AD and the cleverness of the Benedictine monks. The improvements carried out on the land by Cistercian monks of the Chiaravalle Abbey led to the growth of livestock breeding, which soon resulted in large quantities of milk becoming available, far exceeding the needs of the inhabitants.

The origin of Grana Padano is a fascinating tale, dating back to around 1100 AD and the cleverness of the Benedictine monks. The improvements carried out on the land by Cistercian monks of the Chiaravalle Abbey led to the growth of livestock breeding, which soon resulted in large quantities of milk becoming available, far exceeding the needs of the inhabitants.

Consequently, the monks devised the Grana Padano “recipe”, an ingenious way of preserving the surplus milk.

And so a hard cheese was created which, when aged, retains the main nutrients of milk and acquires an unmistakeable flavour, both mild and flavoursome. A cheese which was spontaneously given the name of “grana” due to its characteristic grainy texture.

The reputation of Grana Padano was established over time and the product soon became a highly-esteemed prize ingredient at Renaissance banquets held by princes and dukes, but also a main source of nourishment for people in rural areas during the terrible times of famine. A cheese with two souls: a staple ingredient of recipes belonging to the elaborate cuisine of the nobility and a basic element of traditional everyday cooking.

Over time, the practice of turning milk into “Grana” became more widespread, making it one of the pillars of the farming economy. The traditional methods of producing Grana Padano have been handed down unchanged through the centuries, ensuring that the product continues to display today the characteristics of flavour, aroma and texture, as well as appearance, for which it is world famous.

Grana Padano is a PDO cheese which, as stipulated in the Production Specifications, must be made from raw cow’s milk, originating from no more than two daily milkings and only produced in cheese dairies authorized by the certification body (currently the CSQA).

Grana Padano is a PDO cheese which, as stipulated in the Production Specifications, must be made from raw cow’s milk, originating from no more than two daily milkings and only produced in cheese dairies authorized by the certification body (currently the CSQA).

The inoculated milk is heated to 31°C-33°C, with the calf’s rennet added for coagulation. The curd is broken and cooked at between 53°C and 56°C and stirred. After heating, the grains of curd settle on the bottom of the cauldron where they bind together and are kept in the whey for 30-70 min at a temperature no higher than the temperature at the end of the cooking process.

Leave a comment